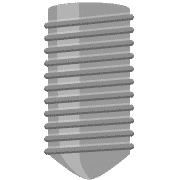

DyzEnd-X Hotend 1.75mm

Produktinformationen "DyzEnd-X Hotend 1.75mm"

Fast Prints

The aluminum melt block transfer heat very quickly to the nozzle for an efficient and very fast printing speed. Furthermore, the long melt zone can handle very high filament feed without any trouble.

Titanium Transition Tube

A titanium alloy has been meticulously chosen to provide both stiffness and low thermal conductivity, limiting heat losses to the cold side.

High Temperature

The high temperature sensor used inside the DyzEnd-X enable precise readings up to 500°C. Any thermoplastics can be used with the DyzEnd-X.

All Metal Melt Zone

The heated zone is made entirely from metals which can withstand very high temperature before losing mechanical properties. Even the sensors and heaters are protected by high temperature resistant sleeves.

Wear resistant nozzle

The DyzEnd-X comes built in with high wear resistant nozzle. The performance have been measured and tested, not only validated on paper.

Cold Swappable Nozzles

By using a very special high temperature sealing washer, the DyzEnd-X is able to switch nozzles at room temperature. No leaks, no burning hazard.

Flexible Filament Ready

The filament is very well guided inside the DyzEnd-X, which allows very high speed with flexible filament.

Jam Free

The DyzEnd-X perform very well in retraction. The secret is its manufacturing process which enable very low friction inside the tube.

High Resolution Sensor

The unique high temperature sensor has a resolution of 0.16°C at 210°C which is better than a amplified RTD sensor and a thermocouple.

Assembled and Tested

The DyzEnd-X is a high-end product and comes preassembled and tested avoiding the user to have any trouble receiving substandard part that are hard to assemble or fit together.

Liquid Cooling Ready

The DyzEnd-X can be easily converted to a liquid cooled setup with Dyze Design’s specialized cooling blocks.

Bowden Ready

The DyzEnd-X is compatible with a M8x1.25 push to connect fitting. The 4mm PTFE tube can be inserted through the connector and guides the filament as far as possible inside the hotend.

Groove Mount

The hotend mounting mechanism is based on the form factor called “Groove Mount”. The 12mm groove makes it very easy to switch and maintain your hotend and nozzle.

Easy to Mount Sensor

The sensor is installed with elegance using a brass housing. This ensure every hotend read the temperature properly without any variation caused by assembly.

Small Form Factor

By using a low conductivity transition tube, the DyzEnd-X is designed very small. This enables you to use your build volume more efficiently.

Fast heating

The DyzEnd-X can heat very quickly. In only 70 seconds, it reaches 210°C.

Unique Serial Number

The unique serial engraved on each hotend protects the product against clones. Also, it assures a tracking of suppliers, assembly and quality reports.

Any Plastics

The DyzEND-X prints all types of plastics:

- Standard: PLA, ABS

- Flexible: TPE, TPU

- Support: PVA, HIPS

- Advanced: PC, PET, PETE, PETG, NYLON

- Engineering: PEEK, PEI

- Metal powder filled

- Wood filled

- Carbon fiber filled

Anmelden

1 Bewertung

5. Dezember 2016 15:00

Zuverlässig und genau!

Endlich ein Hotend die einfach funktioniert. Der DyzEnd-X Hotend lauft bei mir reibungslos seit Wochen. Es ist schenell eingebaut und läuft sofort mit die von der Hersteller angegebene einstellung (Firmware muss angepasst werden, wie mit jede Hotend umbau).