Jetzt neu mit Nema17 0,9° und 200g Gewicht.

Motor: 42BYGHM208P

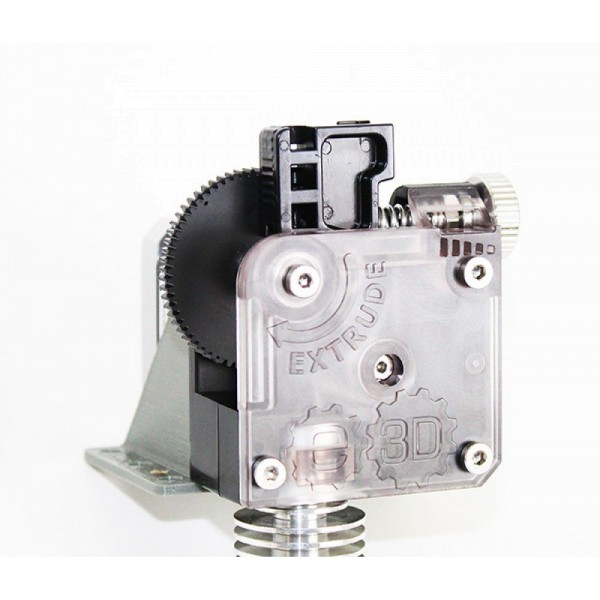

Mirrored Titan

Titan brings high performance, lightweight universal extrusion to everyone!

With the launch of the E3D Titan extruder you have the benefits of geared extrusion but in a lightweight, punchy little package.

Mirrored Titan lets you do even more. Mount two Titans side by side for dual extrusion to maximise your build volume.

Mirrored Titan has the same functionality as the standard version, however the nozzle is offset on the opposite side from usual. For more information please read the wiki!

Titan: A Next Generation Extruder for your 3D printer

Performance. Power. Push.

With 3:1 gear reduction, precision milled hobbed gearing and E3D engineering, we’ve developed Titan to push with awesome power, while also being incredibly light and compact.

The gear ratio means you’re able to use lighter motors as you’ll need less torque for the same filament pushing force - so direct drive systems have a lighter moving carriage, and bowden-style printers become powerful, reliable little beasts when combined with your E3D V6 hotEnd.

Titan fits perfectly into E3D’s modular ecosystem, Titan works for all configurations of bowden, direct extrusion, 1.75mm and 3mm. To switch filament diameters only the filament guide needs to be swapped out, and both 3mm and 1.75mm versions are supplied with every Titan. To use Titan as a bowden extruder you just insert a bowden adaptor into the body instead of a hotend. Bowden adaptors for 3mm or 1.75mm are available as a low cost optional extra.

Speed.

Extruders with high gear ratios often struggle with snappy retracts and keeping up with Volcano for big, fast printing. Titan's balanced gearing ratio of 3:1 means that you can cope with fast extrusion situations like Volcano, and the lightweight gear-set gives snappy retractions.

Resolution

Direct-drive extruders can have issues with ‘pulsing’ of flow, because the lower resolution of filament motion results in filament being extruded in pulses. This results in a slight wavy surface finish, and is particularly prevalent when printing at low layer heights. Using 3:1 gearing triples the resolution of the system and allows for smooth printing at the lowest of layer heights, using the smallest of nozzles.

Every Material.

A fully guided filament path from extruder to print means your filament is carefully guided every step of the way, ensuring a smooth journey to the meltzone. The guide constrains filament throughout the extruder, leaving no gaps and no opportunity for buckling of flexible filaments.

The CNC machined individually cut filament drive teeth allow grip of the slipperiest of Nylons.

A combination of grip and torque allows extrusion of even the most viscous materials like metal filled and carbon reinforced filaments.

1.75mm or 3mm filament: Titan is compatible with either diameter of 3D printing filament, and easily swaps between the two.

The extruder has ample force for even the toughest, gnarliest materials out there, ones that hat would cause lesser extruders to skip, grind or buckle.

Documentation and assembly guidelines can be found on wiki

Key Facts:

- Compatible with all configurations: 1.75mm, 3mm, Direct & Bowden.

- Custom machined 3:1 gear reduction set.

- Highly optimised HobGoblin drive gear tooth profile for maximum grip and consistent steps per mm.

- Fast extrusion speeds for Volcano.

- Plenty of pushing power for small nozzles or demanding filaments.

- Size and weight of a direct-drive extruder (only 90g!), but with power and resolution of a geared extruder.

- Idler tension adjustment with force indicator for repeatable tension settings.

- Easy to use and maintain.

Nema17 40N-cm stepper motor with 24mm D shaft for grub screw and 1.0m wiring.

These stepper motors are smaller NEMA17 Stepper Motors for use on your extruder or printer axes. Being only 38mm long but still producing 40N-cm of torque these motors make an excellent choice for use on your extruder. Lighter and shorter than the standard motors, but producing nearly as much torque. Hybrid.

Property Value

Manufacturer Wantai

Model No. 42BYGHW208P4

Holding Torque 40 N-cm

Shaft 24mm

Rated Voltage 2.55v

Stepping Angle 0.9°

Rated Current 1.2A

Lead Length 1000mm

Capricorn Bowden Tubing (10cm)

Capricorn Bowden Tubing (10cm)